Marine loading arm systems ensure efficient and safe liquid transfer operations in the marine environment. These robust and versatile systems comprise a series of articulated arms linked to flexible hoses, enabling seamless connection between vessels and shore-based facilities. The arms are equipped with advanced controls for precise movement and positioning, minimizing spills and ensuring the safe transfer of a wide range of liquids, including crude oil, refined petroleum products, chemicals, and marine gases.

A key advantage of marine loading arm systems is their ability to operate effectively in demanding weather conditions. The arms are designed to withstand high winds, waves, and currents, ensuring a stable and secure connection between vessels and ports. Furthermore, these systems incorporate safety features such as emergency shut-off valves and pressure relief mechanisms to prevent the risk of accidents.

- Marine loading arm systems are essential for safe and efficient liquid transfer operations at sea.

- They play a critical role in various industries, including oil and gas, chemicals, and manufacturing.

- Advancements in technology have led to the development of more sophisticated and reliable marine loading arm systems.

Top Loading Arms for Bulk Chemical Handling

Bulk chemical handling necessitates safe and efficient transfer processes. Top loading arms play here a vital role in this regard, providing a secure and reliable method for loading and unloading bulk chemicals from storage tanks or railcars. These specialized arms possess a robust design constructed from corrosion-resistant materials to withstand the corrosive nature of many chemicals. Their adaptable configurations allow for precise positioning and connection to various container types, ensuring safe and accurate fluid transfer. Top loading arms are equipped with integrated valves that enable operators to adjust the flow rate and direction of the chemical being handled. This level of control minimizes spillage and potential hazards during movement. Moreover, top loading arms often integrate safety features like pressure relief valves and emergency shut-off mechanisms to prevent risks associated with accidental leaks or surges.

Tanker Unloading Arms: Safe and Reliable Tanker Unloading Solutions

When it comes to effectively unloading tanker trucks, bottom loading arms are the preferred solution. These robust systems ensure a safe and reliable way to transfer liquids from tank vehicles to storage tanks. Bottom loading arms are designed with multiple security features, including automatic stop mechanisms, preventing spills and contamination.

- Furthermore, bottom loading arms are built for strength to withstand the challenges of everyday activity.

They can be custom-configured to meet the specific specifications of various sectors, providing a secure and reliable unloading process.

Boosting Marine Operations with Automated Loading Arms

In the dynamic world of marine logistics, efficiency is paramount. Automated loading arms are emerging as a game-changer that can significantly improve the loading and unloading processes across various maritime industries. These sophisticated systems offer exceptional accuracy, rapidness, and security compared to traditional manual methods.

By minimizing human intervention in the loading and unloading procedure, automated arms reduce the risk of accidents. Their precise control ensures that cargo is transferred accurately and swiftly. Moreover, these systems can be connected with other maritime technologies to create a seamless and optimized operational workflow.

Selecting the Right Marine Loading Arm to Your Needs

When it comes to marine loading arms, selecting the right one is crucial in ensuring smooth and efficient operations. Consider factors such as the type of cargo being handled, the viscosity, and the required flow rate. Also, environmental conditions and safety regulations should be taken thought. A properly selected marine loading arm will minimize spillage, decrease operational downtime, and enhance overall safety.

- Consult a qualified supplier who can guide you in selecting the most suitable marine loading arm to meet your specific needs.

- Explore different manufacturers and their product offerings to gain a comprehensive understanding of available options.

- Emphasize factors such as durability, withstanding corrosion, and ease of maintenance when making your selection.

Ensuring Safety of Regular Maintenance for Loading Arms

Regular maintenance of loading arms is paramount to guarantee safe and efficient operations. Over time, wear and tear can compromise the integrity of these critical pieces of hardware, leading to potential incidents. A detailed maintenance program helps reveal issues before they become serious, minimizing downtime and possible damage.

- Regular inspections should include checking for wear, seals, and the overall stability of the loading arm.

- Lubrication of moving parts is essential to prevent friction and prolong the lifespan of the equipment.

- A well-maintained loading arm operates safely, ensuring the smooth movement of materials.

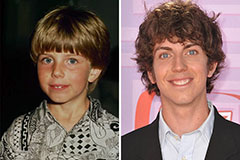

Jonathan Taylor Thomas Then & Now!

Jonathan Taylor Thomas Then & Now! Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Michael Oliver Then & Now!

Michael Oliver Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now! Nicholle Tom Then & Now!

Nicholle Tom Then & Now!